We combine different technologies

Polymer composites are used to produce moulds for polyester-glass and epoxy-glass laminates. The role of the matrix is played by suitable resins (polyester, epoxy or vinylester), and glass fibres or fabrics are used as reinforcement. Depending on the application, we create rigid moulds – often additionally reinforced with laminated profiles – and flexible moulds made of polyurethane or silicone. Plastics produced in this way provide:

- high mechanical strength,

- low weight,

- chemical resistance,

- adaptable to specific needs.

We create both rigid and flexible molds from polymer composites consisting of polyester-glass laminate or epoxy-glass laminate. In specific cases, we use fiberglass or fabric, with the polymer matrix being made of vinyl ester. For mold production, we use tool polymers, often additionally reinforced with laminated profiles. Flexible molds, on the other hand, can be made from polyurethane or silicone.

We combine different technologies to achieve the best results.

Production methods

Hand Laminating - HANDY-LAY-UP

The manual molding method, in which the product is created by applying successive layers of appropriate supporting materials. The outer surface of the product is coated with gelcoat, which is applied first in the technological process using either a manual method or spray application (with the use of a special machine – SPRAY/GUN version).

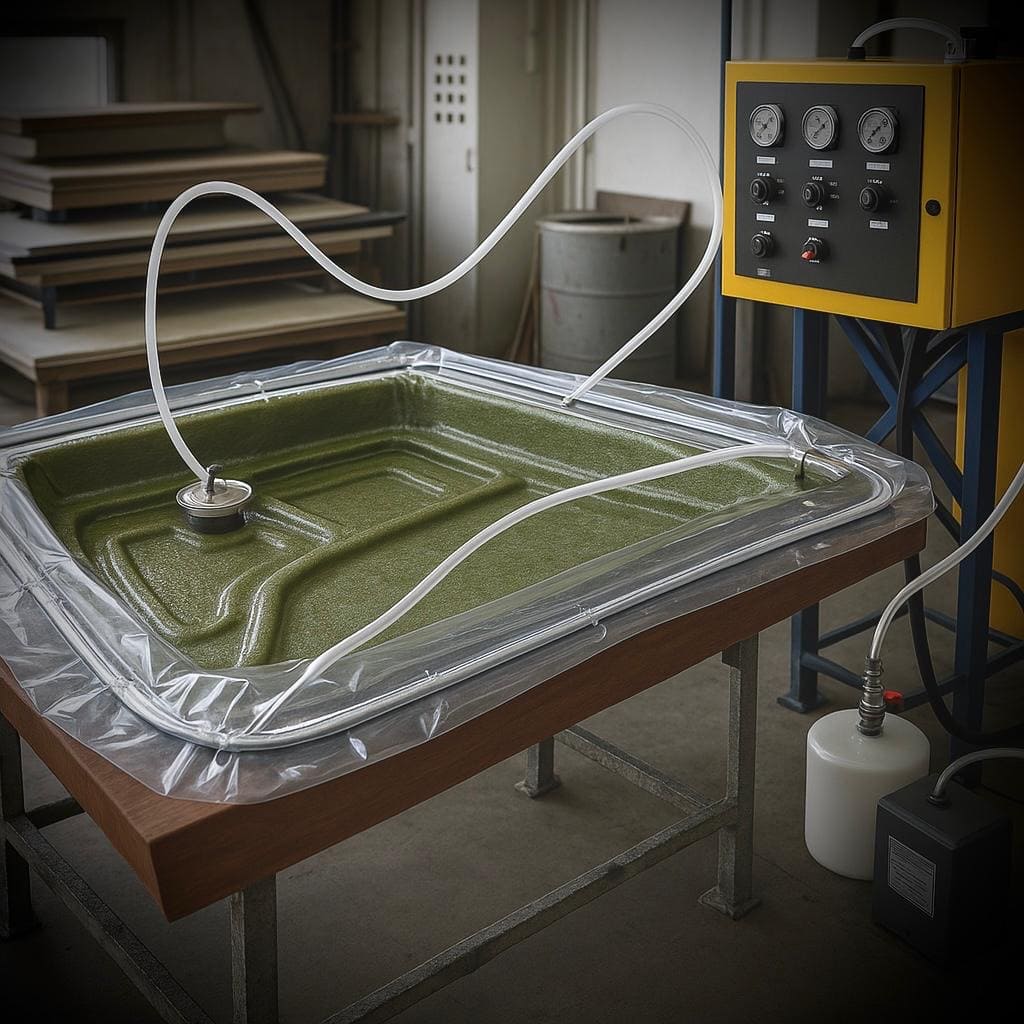

Vacuum forming

The method of producing products using a closed mold. Initially, as with the manual method, gelcoat is applied (either manually or via SPRAY). In the next stage, supporting layers (glass mats, technical fabrics, synthetic mats, sandwich mats, core mats, rovicore, etc.) are laid onto the mold, along with any reinforcements and adaptations if necessary.

After this operation, the mold is closed, which can be done using a specially prepared diaphragm made of PWS laminate (a plug) or a diaphragm made of a plastic or silicone bag. In each case, a key aspect is ensuring the tightness (hermetic sealing) of the mold.

Injection methods – RTM

The use of compressed air, special clamps, actuators, or presses ensures proper pressure on the mold parts. Due to the large closing forces and (during production) the pressure associated with resin injection, molds in this method must have adequate strength. For this purpose, special pastes, composite materials, as well as metal frame structures and reinforcements, are used.

After the mold is closed, the resin is injected through a special opening (or openings) made in the mold.

We offer not only our products and production services but also full comprehensive support, professional painting in any type and color, as well as assembly.

What can we offer you?

Sleeping cabins and spoilers

for relevant types of cars, Citroen Jumper, Renault Master, Peugeot Boxer, Fiat Ducato

Tuning

spoilers, fairings, mudguards, bonnets, carbon elements and many other components

Industry

components for trains and buses and aircraft, tanks, sleeping cabins, engine housings for machines

Home and garden

pots, armchairs, sun loungers, tables, 3D wall panels, bath tubs, wash basins, chairs, swimming pools, slides